Trumpf TruMark Laser Adds Part Marking and Part Serialization Capability

Part identification and part traceability is always a important process when manufacturing parts. In the case of medical tooling, medical equipment and medical components, part traceability creates a direct link from the quality system of our customers to the quality system in place at Marten Machining.

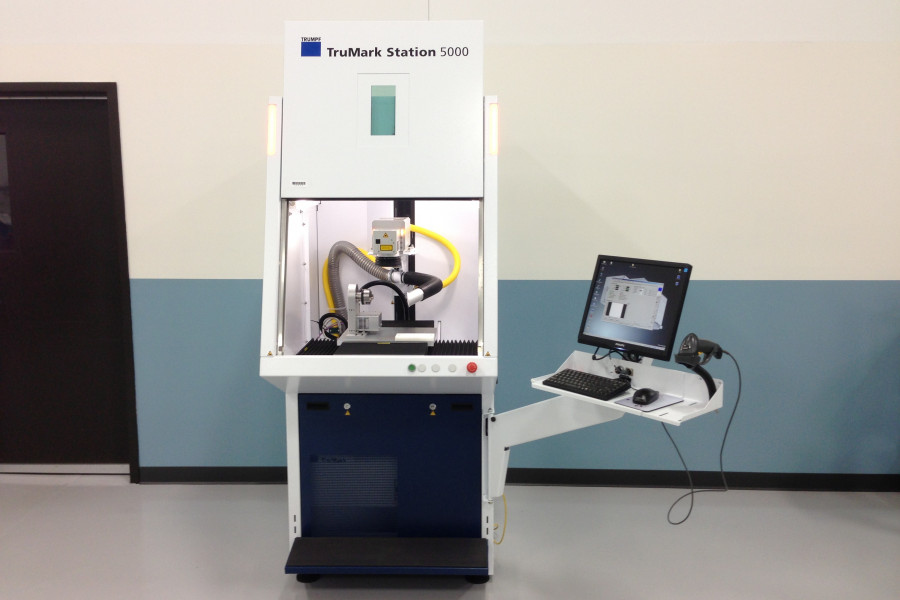

To meet the increasing demand for part serialization and also for more complex part marking Marten Machining has added a Trumpf TruMark 3020 1064nm marking laser housed in a TruMark 5000 marking station. The laser marking head of the TruMark 3020 laser source has the ability to create monochromatic characters and designs on metals and also can mark some plastic materials. Marten Machining has also developed marking processes for unique part serial numbers and part identification numbers that can tie directly into part inspection information recorded during manufacturing or final inspection. The Trumpf TruTops Mark software has the capability to adjust marking parameters so that marks can achieve a balance between marking surface appearance and marking durability depending on the specific material, part geometry and underlying part surface finish.

An added option on the marking station has proved to be the biggest surprise. The motorized and programmable A axis turret can be used to make marks around the circumference of small diameter pieces. In one case already the laser was used in an application to replace a rotary tool that was prone to wear during the marking cycle. The laser proved to be a repeatable and efficient way mark a .125" diamater in a molybdenum material and also decreased marking cycle time by 65%.

The laser has also been a large help with Marten Machining's gage calibration program. Annealing marking parameters were used on inpection hand tools to mark gage identification numbers that correspond to the inspection certificate database used for all gages in the facility and the laser marks will serve as a secondary identification in case calibration stickers get damaged or lost.

Like many other support pieces of equipment that have been pruchased by Marten Machining in the past several years the Trumpf laser has found ways to be valuable on multiple levels of the manufacturing process.