You show us a part and we'll show you a solution.

And we partner with you to plan it, make it, measure it, and design a process for optimizing manufacturability.

Advancing manufacturing through talents and technology.

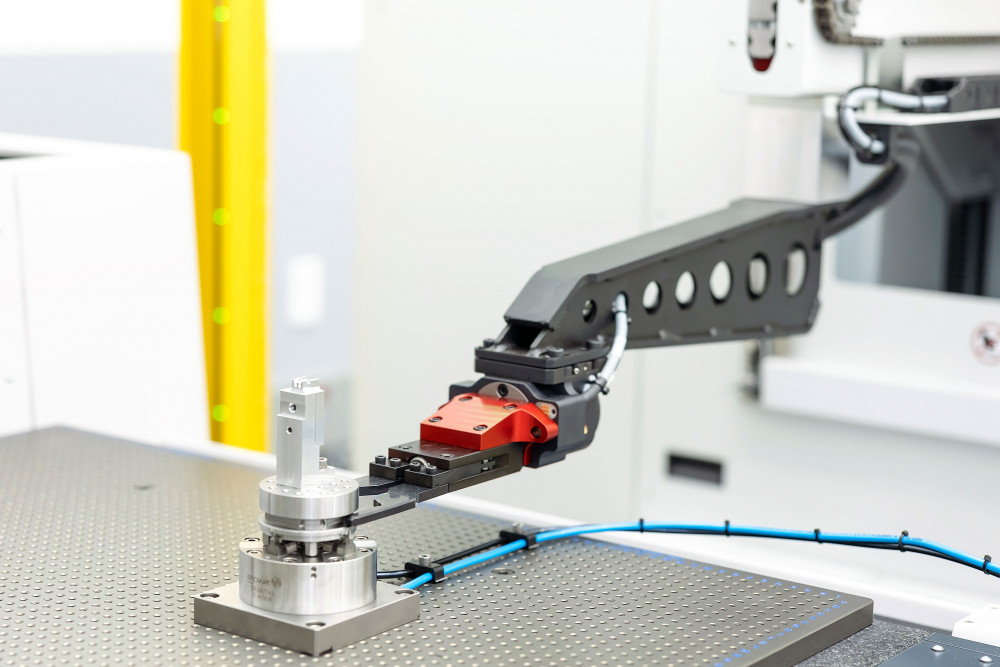

Talented people working alongside some of the finest technology available is the best way to move advanced manufacturing to the next level. And at Marten Machining, we respect both.

The concepts of measurement don't change.

They just need to be applied using modern technology.

You can’t talk about machine tool technology without talking about respect for the process of Metrology. That’s because precision measuring is the backbone of precision manufacturing and that’s one of the only ways to bring advanced manufacturing to the next level.

Proven methodologies applied to a diverse range of materials

Some of the many materials we work with include:

Special Alloys

- Inconel

- Titanium

- Tungsten

- Nitinol

- Eligiloy

- Carbide

- Molybdenum

Precious Metals

- Platinum

- Gold

Plastics

- PEEK

- Torlon

Stainless Steel

Copper

Ceramics

We manufacture for your research & development.

At Marten Machining, we excel at partnering with you to design a process for optimizing manufacturability.